SWASTIK PERFORATORS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SWASTIK PERFORATORS

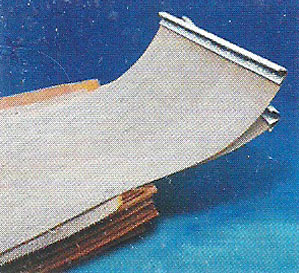

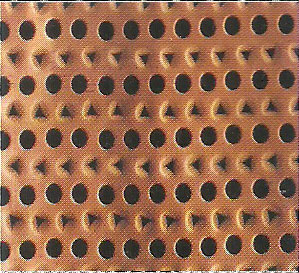

Cetrifugal Working Screen

Product Range of Centrifugal Screens :-

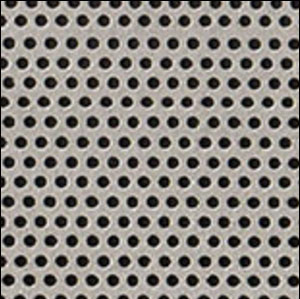

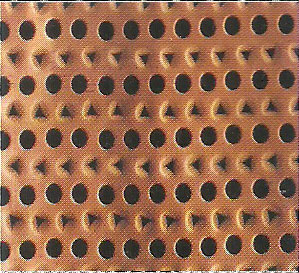

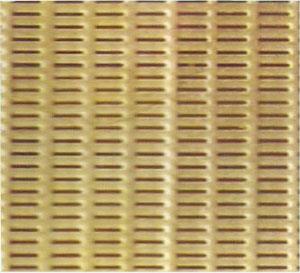

Working Screens : Having Conical Round Holes & Elongated Taper Slot in copper , Brass and S.S Metals and steepcone Basket Screens duly welded & silver Brazed with jointing Strips.

Supporting/Backing Pattern : Wire Nettings , Plain & Dovex type Triangular stabbed with Round Hole, Stabbed Hole , Perforated & Corrugated in All Metals.

Others : Sugar Grader Mesh , Mogensen Screens , Nickel Screens, DSM Screens, Bagacilo Screens

Important Suggestions

All Screens for Centrifugal Machines Manufacture of costly metals ,variation of thikness direct effects its pricing ,consumption, durability, labour cost & economy of Sugar Mills. To avoid this pilferage and procurement of quality screens consider our suggestions as under :-

Prefer to purchase copper/brass screens at rate per K.G basis instead of per piece and verify thickness from weight chart.

For durability and better results brass screens should be 63cu : 37zn and copper screens should be 99.9 purity.

Stenless Steel Screens should be of 304 grades as specified in vaccum filter screens specification on back page.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.